Jiakaicheng Wealth Center, Financial Third Street, Jiangsu Province, China

Product

Home / Product / Foundry industry

Detail

|

Products |

Raw materials |

technique |

Processes |

Applications |

|

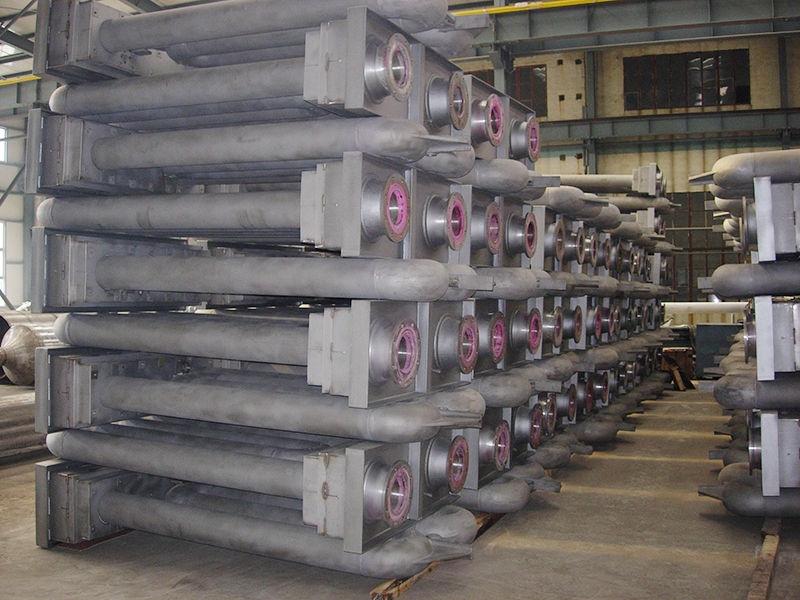

Hydrogen conversion equipment |

Fossil fuels (oil, natural gas, coal gas), tail gas recovery (methanol cracking, ammonia, coke oven gas) |

Steam reforming is the process of reforming hydrocarbons such as methane with water vapor in the presence of a catalyst and at high temperatures to produce H2. |

Each tube of the light hydrocarbon steam reformer is a flame directly heated reformer reactor, the tube is filled with catalyst, the process medium (hydrocarbon and water vapor) while absorbing heat to carry out complex chemical reactions, the common types of furnaces are top burner, side burner, ladder furnace. Conversion pipe system is generally a single pipe type, including the conversion pipe, upper and lower tail pipe and upper and lower gas collection pipe, the total collector and branch collector, hot wall/cold wall collector (lined or unlined), gas pipeline, pigtail pipe, etc., the inner surface is processed to remove the loose layer of centrifugal casting, in the furnace for the heating section, the catalyst is set up at both ends of the flange and flange cover. |

Oil refineries, ammonia plants, methanol plants and other petrochemical enterprises |

Centrifugal casting: HG/T2601, ASTMA608, DIN10295, JISG5122

Static casting: HG/T3673, ASTMA351

It can also be produced according to customer requirements or other specified standards.

The products are mainly used in methanol hydrogen production reforming furnaces, caprolactam reforming furnaces, and fertilizer reforming furnaces.

Major customers include PetroChina and Sinopec. Since 1999, it has successfully delivered more than 30 projects to PetroChina, Sinopec and other petrochemical companies.